Instant fluid conditioning. Faster wellbore construction.

Enhances mud flow characteristics for more efficient drilling.

Stabilizes emulsions, improves mud integrity under load.

Improved well integrity.

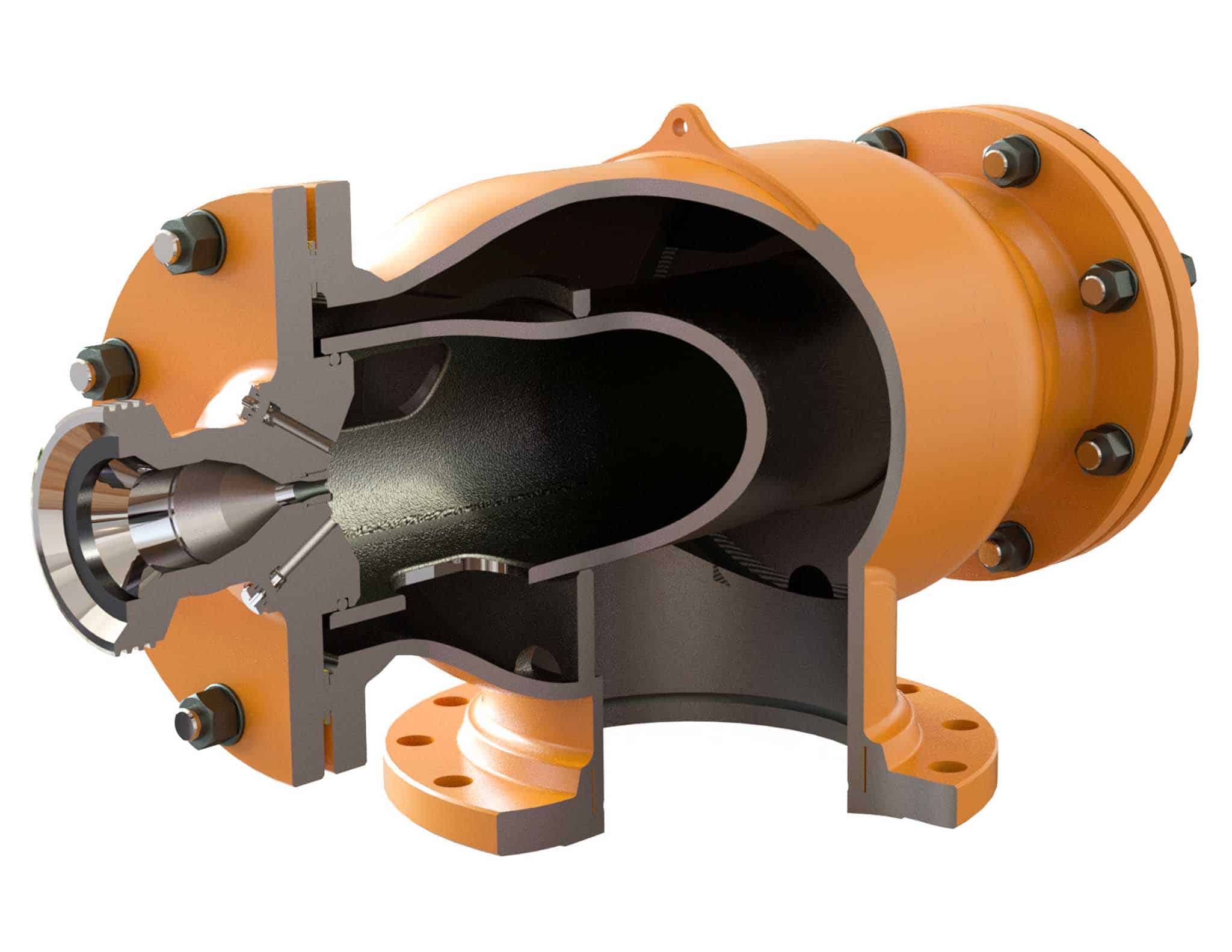

The Dual Shear Gun is Jagtech’s advanced rigsite tool for on-demand drilling fluid optimization. Designed to rapidly shear and stabilize mud just before it enters the well, it delivers instant rheological performance – No need for prolonged circulation or waiting on mud conditioning.

By instantly improving viscosity, electrical stability (ES), and emulsion quality, the Dual Shear Gun ensures your drilling fluid is always fit for purpose – Even in high-pressure, high-temperature (HPHT) or deepwater environments.

Operators use the Dual Shear Gun to cut prep time, stabilise fluids, and keep drilling operations on schedule.

With the Dual Shear Gun, your team can skip lengthy circulation cycles and pump fully conditioned fluid directly into the wellbore.

That means less downtime, faster progress, and better control.

The Dual Shear Gun is a high-performance tool used in drilling operations to rapidly condition and homogenize drilling fluid. Traditional methods often require extended circulation time to achieve desired rheological properties – wasting both time and energy. This tool enables instant shearing of mud on-site, ensuring that drilling fluids exhibit optimal viscosity, emulsion stability, and flow behaviour before being pumped into the wellbore.

By boosting the Electrical Stability (ES) value of oil-based muds—sometimes by as much as 100%—the Dual Shear Gun helps maintain a consistent and resilient fluid system. This is particularly critical in deepwater wells, high-angle drilling, or any operation where fluid performance is directly tied to hole cleaning, pressure control, and rate of penetration (ROP).

Jagtech’s solution is compact, easy to operate, and rig-ready. Whether you’re optimizing a new well or maintaining fluid properties mid-operation, the Dual Shear Gun helps operators reduce non-productive time (NPT) and stay on target.

For operators looking to streamline drilling fluid management and gain tighter control over wellbore construction timelines, the Dual Shear Gun offers proven performance in a robust, field-tested package.

Let’s discuss how the Dual Shear Gun can fit into your operations.

Use the form below and a Jagtech expert will be in touch.

"*" indicates required fields

Everything you need — specs, use cases, and performance data.