In the following it is described why shearing of drilling fluid is essential to prevent sag and why this sag prevention cannot be predicted based on API viscometer readings.

Barite sag is a phenomenon that is difficult, or impossible, to determine from standard viscometer measurements [1]. It is shown that for creating a sag free fluid it is necessary to create a locally solid like structure in the fluid even though it is in a liquid state. Thus, the elastic responds must be larger than the energy loss responds in the fluid. This is possible in a water-based drilling fluid, but not in an oil-based fluid.

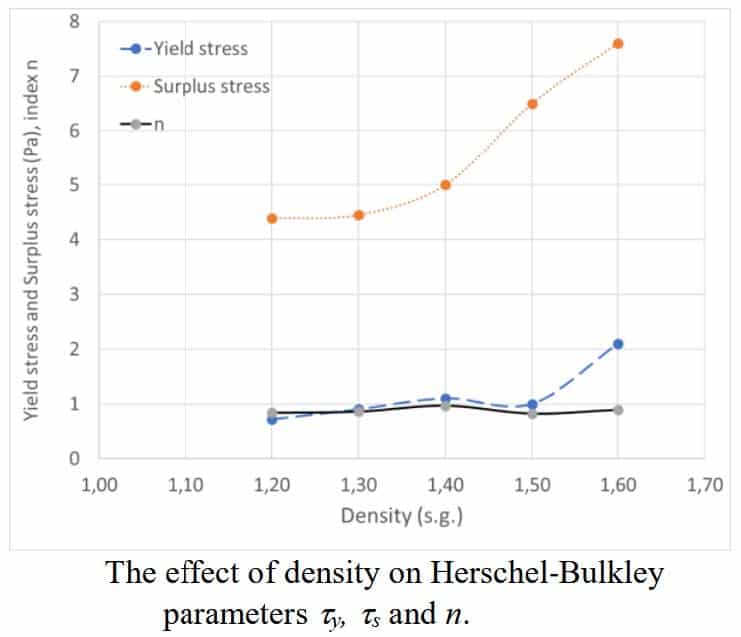

There are no real gels formed in an oil-based drilling fluid. The fluid is thickened by having Brownian motion to develop a geometrical structure of water droplet placements. Adding barite will of course increase the density of the drilling fluid, but it will also affect the viscosity. It will also bring more particles with a huge surface area into the fluid and thus increase the overall viscosity as shown in the figure below [2]. Here, the Herschel-Bulkley form is presented with dimensionless shear rates providing the viscosity of the drilling fluid to be proportional to the sum of yield stress and surplus stress at shear rates relevant for the drilling operation [3].

The Bingham model based on API or ISO procedures will normally not provide adequate viscosity values for the shear rate ranges appearing during drilling in normal oil wells. The Bingham yield stress is frequently far out of scale compared with the real yield stress. Use of YP should be performed only with great care. The Herschel-Bulkley model approximates drilling fluid viscosity over a large range of shear rates. However, the model will not always describe the drilling fluid viscosity accurately for all shear rates. Often, if accurate at lower shear rates, the model will be inaccurate at high shear rates and vice versa. The Zamora and Power low shear yield stress (LSYP in API specifications) seems to approximate the yield stress with sufficient accuracy for most applications. Drilling fluid engineers should take care to obtain proper measurement quality at all shear rates. If accurate measuring systems are used, a better model is obtained if the data are collected and discussed for the relevant shear rates. The viscosity parameters in the traditional way of presenting the Herschel Bulkley model cannot be used to compare drilling fluids. The complete flow curve must be used in the comparison [3].

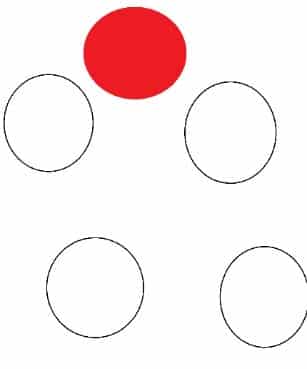

Sag in water-based drilling fluids has its highest severity at 1.55 sg [1]. However, because of the nature of polymers in water-based drilling fluids, sag is not a problem in water-based fluids as long as the polymers creates sufficient network and are well dispersed. For higher densities the sagging barite particles will create a counterflow helping to disperse the barite. The situation is more complex for oil-based drilling fluids. There are normally no real network creating a real yield stress or a real gel structure. The viscosity is constructed by adding emulsified water with additives working in the oil-phase between the water droplets. Because of the particle size distribution (PSD) of barite, the oilfield viscometer size is constructed with a viscometer gap somewhat larger than 1mm to provide viscosity data relevant for frictional pressure losses in the drill pipe and in the annulus. As mentioned above barite act like a viscosifier in addition to act as a weighting agent. Thus, sag cannot be determined by the properties of a fluid volume being much larger than the individual barite particle volumes. The interesting parts controlling the sag is likely to be due to the droplet emulsion as the emulsion forms the fluid volume relevant as the base fluid for the barite particles. The flow of barite is a two-phase flow where the barite meets fluid built with smaller items than the barite. If we have an oil water ratio o/w~80/20, and relatively homogenous droplet sizes, the average distance between water droplets will be similar to the droplet size independent on the droplet size. In an illustration example shown below we can see for an un-sheared drilling fluid that many barite particles, with particle D50 sizes around 20 micron, see a free oil channel to sag rapidly down in. It is only the base oil viscosity that is preventing sag in this case.

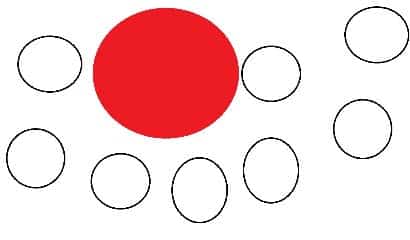

If we now shear the drilling fluid properly, the individual droplet size is significantly reduced. Still, the inter-droplet distance is equal to the droplet size; but now being smaller. The barite particle size has not been changed by shearing. But the barite particle cannot sag freely without making a collision between water droplets, and some tendencies of droplets leapfrogging. This droplet-droplet interaction increases the viscosity significantly seen from the barite particle. Hence sag is reduced by shearing.

The droplet-droplet interactions that increase in the viscosity significantly on micro scale that was described above, may or may not be observed when measuring the viscosity of the drilling fluid volumes measured using API described viscometers as these API measurements are measuring the total effect over a significantly larger distance.

In a shear test at a drilling fluid plant, a volume of 25 m3 drilling fluid filtrate was sheared. We never observed any change in filtrate viscosity when measured in accordance with API specifications. However, the electric stability (ES) was significantly increased, indicating breaking up droplets to smaller droplets.

On a Norwegian offshore operation, the shearing device has been in continuous use for the last two years. Because of running an MPD operation in a very weak formation, the drilling process itself cannot provide sufficient shear of the fluids. The Dual Shear Gun was introduced as the shear field is strong enough to reduce droplet size and at the same time the jet collision was gentle enough for some other solid not to be de generated. (Carbonate particles are still anticipated to be de-generated in size simply by the shear). In the Norwegian field, the Dual shear gun proved to be efficient both for traditional oil-based drilling fluids viscosified by organophilic clays and fluids also viscosified by use of polymeric modifiers. The tendency of severe sagging was removed. In this case only a minimal increase in low-shear viscosity was observed. But as we have seen, this value may be of lesser relevance for the sag process.

References:

[1] Saasen, A., Liu, D., Marken, C.D., Sterri, N., Halsey, G.W. and Isambourg, P., “Prediction of Barite Sag Potential of Drilling Fluids from Rheological Measurements”, paper IADC/SPE 29410 presented at the 1995 IADC/SPE Drilling Conference, Amsterdam, 28 Feb-2 March, 1995, pp. 663-671. [2] Halvorsen, H., Blikra, H.J., Grelland, S.S., Saasen, A. and Khalifeh, M. 2019. “Viscosity of Oil-Based Drilling Fluids”, Ann. Trans. Nordic Rheol. Soc., vol. 27, pp. 77-85. [3] Saasen, A., and Ytrehus, J.D. 2020. Viscosity Models for Drilling Fluids – Herschel Bulkley Parameters and Their Use”, Energies vol. 13, no. 20, 5271. https://doi.org/10.3390/en13205271.