Magnetic Separation for Cleaner Mud – Dual MAPS System Results Offshore Norway

At the Ivar Aasen Field, a major operator in Norway evaluated the Jagtech Dual MAPS System to improve drilling fluid quality and directional accuracy. The system efficiently removed metallic contamination from the mud, enhancing drilling stability and data reliability.

Results and performance observations were later shared in SPE-215604-MS.

Technology applied

Jagtech Dual MAPS System (Metallic Active Particle Separator)

A flow-positioned magnetic separator engineered to:

- Cover the full flow cross-section with magnets arranged in a defined grid

- Use titanium rods with stacked neodymium magnets for high field strength

- Feature an integrated scraper and semi-automatic cleaning system for safer handling

Customer results

The operator reported:

- Up to 7× higher efficiency in removal of metallic particles than comparable magnets

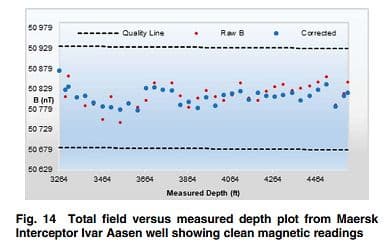

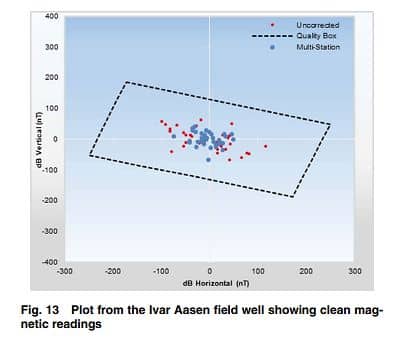

- Improved data collection and reduced measurement error

- Improved well-placement accuracy and lower well cost after installation

Cleaner drilling fluid contributed to steadier directional steering and improved reliability of measurement tools during drilling.

Operational insight

The semi-automatic cleaning setup reduced manual work, improved HSE conditions, and maintained consistent capture efficiency throughout operations.

Reference

SPE-215604-MS – Removal of Magnetic Metallic Contamination – Improved Drilling Fluid Performance, Offshore Europe Conference 2023.