Automated ditch magnet for safer removal of magnetic debris to obtain cleaner drilling fluids.

Fully automated magnet system- no lifting, exposure, or manhandling.

Removes ferrous debris for better signal-to-noise ratios.

No skin contact, fumes, or pinch risk; less deck spill.

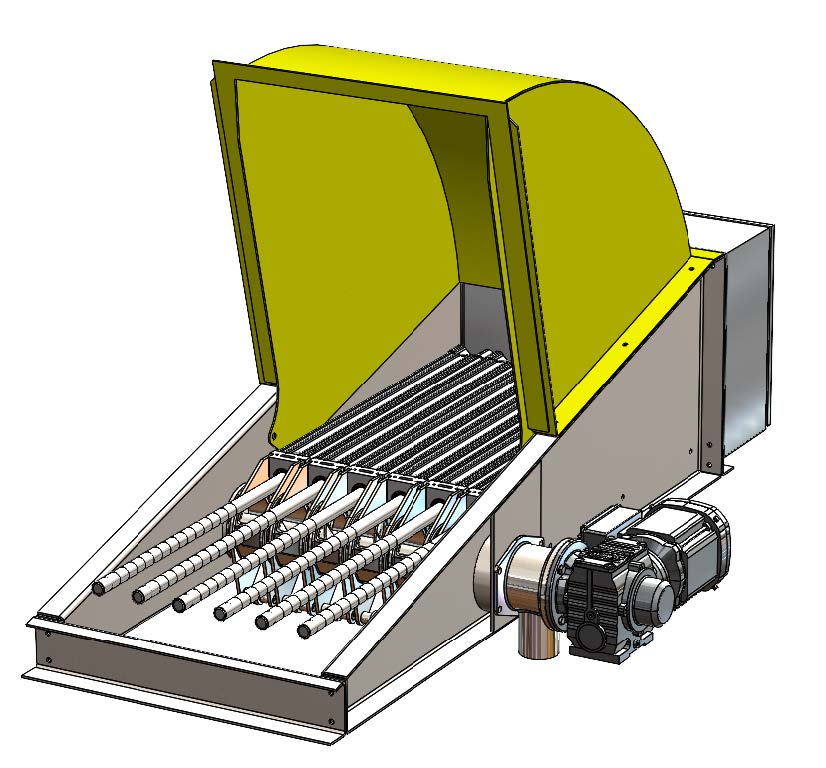

AutoMAPS is an automatic flowline magnet system developed by Jagtech to replace manual metal particle removal processes on drilling rigs. Unlike conventional magnet bars, AutoMAPS is automatic operated, pneumatically controlled, and can be fully integrated into the rig’s solids control system.

This magnetic particle separator ensures continuous metallic particle removal without direct human intervention- improving safety, performance, and environmental issues.It also improves performance since the magnet rods never gets saturated.

Drilling fluid performance depends on clean, consistent returns. Manual ditch magnets expose workers to:

AutoMAPS solves this by automating the entire cycle, improving HSE compliance, minimizing risk, and supporting MWD accuracy by keeping mud cleaner.

AutoMAPS is engineered to operate inline or on the flowline using:

This design allows operators to configure the system by rig layout, automate cleaning based on metallic particle accumulation, and avoid manual exposure completely.

AutoMAPS is trusted in:

An automatic ditch magnet is a system that removes ferrous particles from drilling fluids without manual handling. AutoMAPS automates this process for improved safety and fluid quality.

Metal particles of all kinds interferes with downhole tools like MWD/LWD. Removing it improves tool reliability, signal quality, and wellbore cleaning.

Yes. AutoMAPS is certified for ATEX Zone 1, IIB and meets IP65 protection standards, making it suitable for hazardous rig environments.

Let’s talk about how AutoMAPS fits your operation.

"*" indicates required fields

Everything you need — specs, use cases, and performance data.